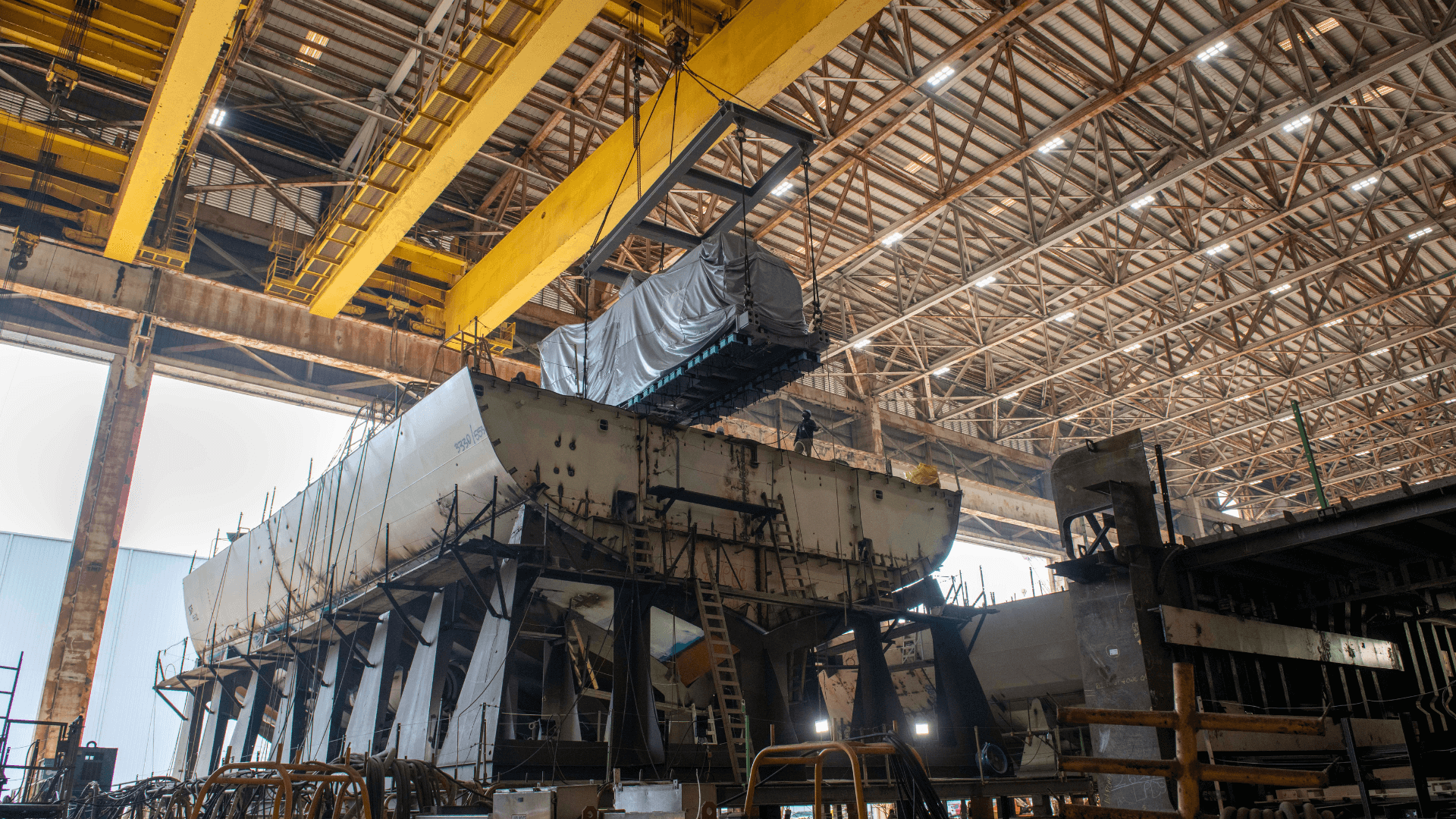

As shipbuilders work through the intense summer months, Ingalls continues to find ways to stay cool. The chill water air conditioning units installed on George M. Neal (DDG 131) is a pilot program to help combat heat stress.

“We are trying a chilled water system, piping in cold water to interior air conditioning units deep inside the ship,” said Justin McArthur, director, Facilities & Maintenance. “Instead of pumping the air through the shell of the ship and into the interior, this system will minimize travel time for the air and maximize efficiency.”

The chill water units in the ship creates a cool down zone for shipbuilders to use during the day. They are strategically placed within the ship to lower temperatures in key spaces.

“Currently, we are seeing a 10-15 degree drop in temperature in the designated areas,” said John Santalla, analyst, Health & Safety.

This pilot program is one of the many tools Ingalls provides for shipbuilders to help them combat extreme temperatures while still maintaining production.

“If we have a heat stress incident, the chill water units aren’t far away from any spot at any given time,” said Demetrius Ramsey, analyst, Health & Safety. “We can send that shipbuilder to a cool-off zone, give them a break from the heat and make sure they are able to return to work.”

With this program, the units help catch early symptoms of heat stress before it progresses.

“It’s extremely hot in Mississippi this time of year, and we will continue to support our shipbuilders in these conditions,” said Brian McVey, director, Environmental Health & Safety. “This pilot program is an example of making things easier for them to successfully complete their tasks.”

__PRESENT

__PRESENT__PRESENT