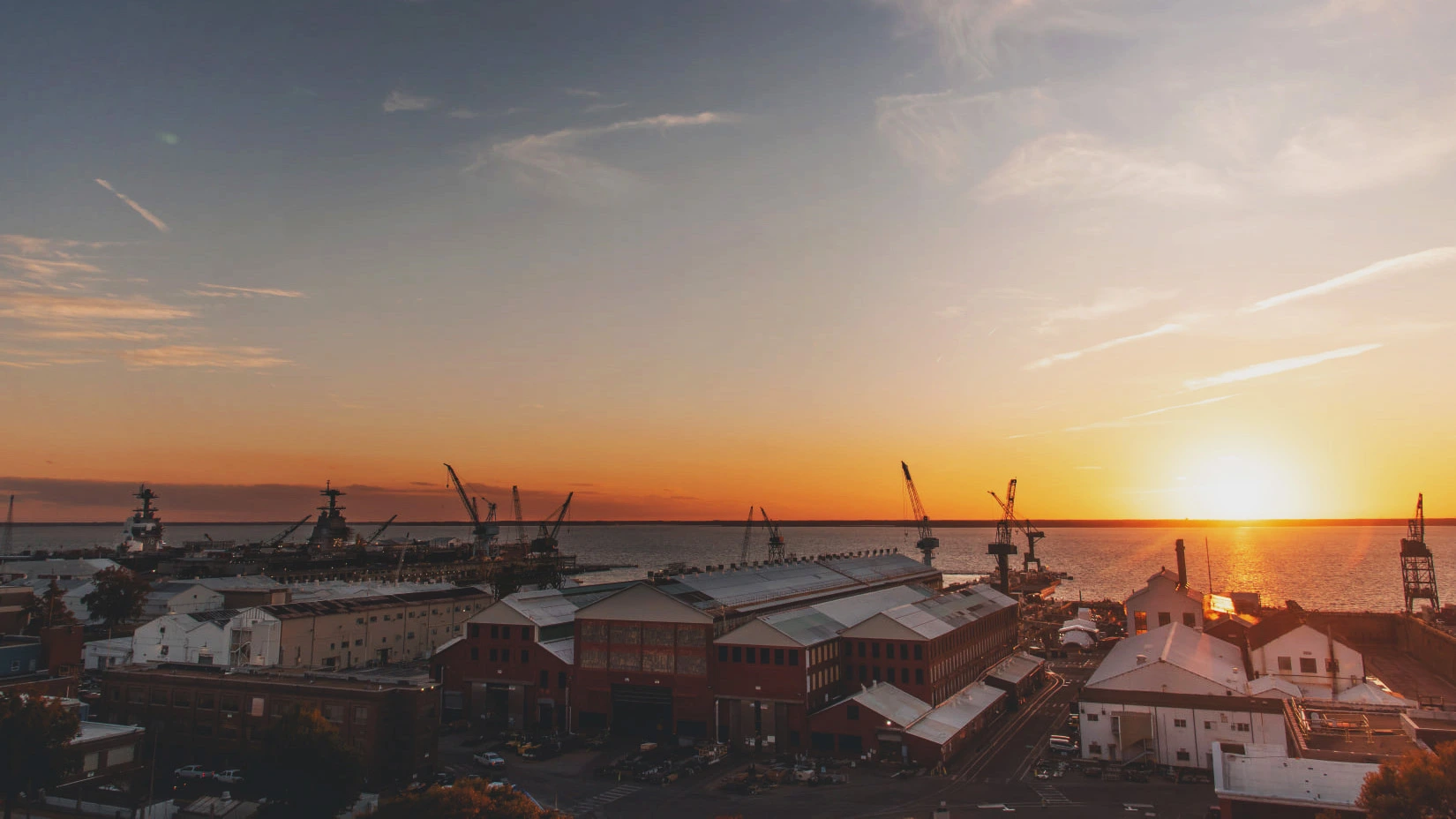

Deckplate Standards (DPS) provides a set of best practices for preparing, assigning and completing work, and the approach has paid dividends aboard USS John C. Stennis (CVN 74).

Teams of shipbuilders working on the aircraft carrier’s refueling and complex overhaul (RCOH) have seen noticeable improvement in the completion of work since the system was introduced last fall, said Callon Thompkins, a lead general foreman.

“DPS lays out the basic expectations, and it drives a specific focus that leads to being efficient and showing success at every level,” he said.

Since the implementation of the system, X42 pipefitters have seen a 21% improvement in work packages completed. Machinery Installation has logged a 16% increase.

The systematic approach allows work to be broken down at different levels, as appropriate.

“I would identify a holistic approach for my department, a large volume of work,” Thompkins explained. “Then it breaks down to my general foremen in their specific areas of responsibility. They lay out more specific goals that equate to that work finishing within a certain time and cost. Then, that general foreman works with the foreman to lay out the goals directly. Then, the foreman breaks it down to the mechanics.”

The bottom line, he said, is that “it puts things right in front of your face.”

It involves regular communication and weekly goals, so leaders can praise success and address challenges right away. It also reinforces common-sense practices, such as making sure incomplete work is documented and handed off to the next shift, assigning clear job instructions and goals for the day, and encouraging coaching.

The DPS approach has relevance in other production areas of the shipyard, but the Stennis teams are farther ahead than others.

“The teams are a hundred percent in,” he said. “They see the goodness in it, with hitting their goals or beating their targets.”